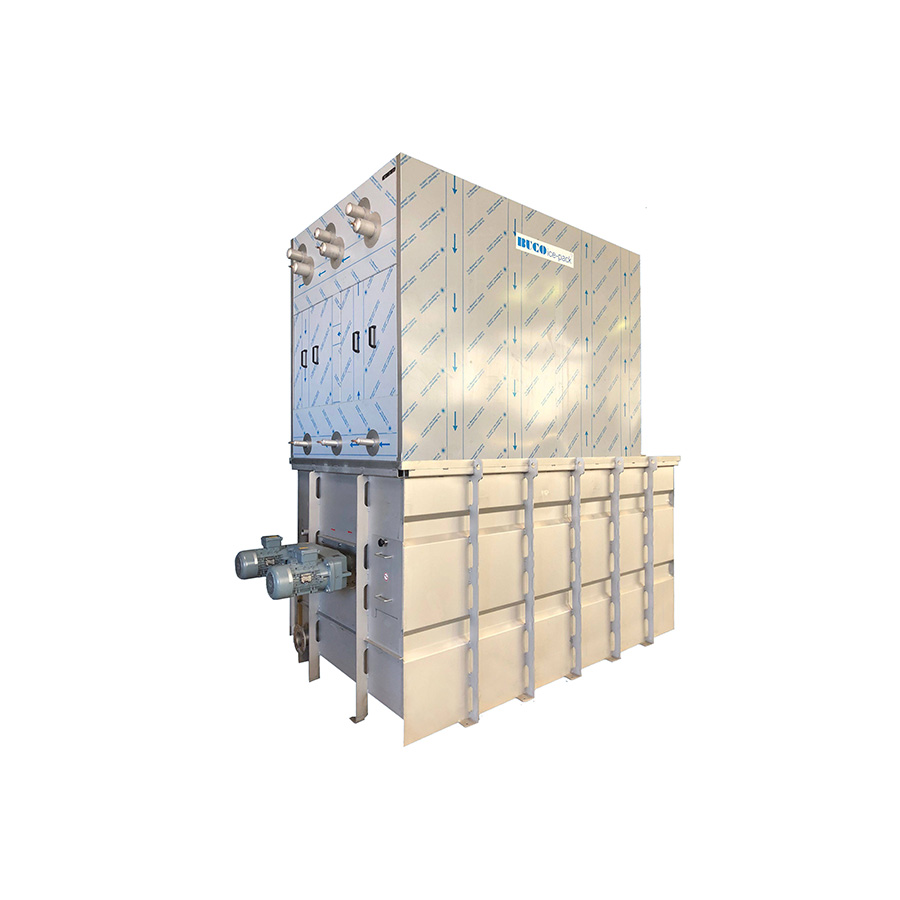

Industrial Ice Maker

The efficiency of the dynamic ice making is based on the big evaporator surface, which allows much more efficient evaporation temperatures compared to other systems that use small evaporator drums and mechanical scraper. Drum systems work with evaporation temperatures between -20°C and -30°C. The BUCOIce Pack works between -8 and -10 °C. That saves energy for electrical drives and allows to make ice for about half the Price.

Fields of Application:

- Industrial chilling with peak loads: Production of food, dairies, breweries and production of soft drinks.

- Chilling in the production of concret, chemicals and pharmaceuticals.

Benefits:

- Consumable ice for direct cooling of products

- Increasing of cooling effect by direct contact with ice

Technical Specifications:

- Chip ice, not subcooled, no sharp edges

- 5 – 150 ton ice/day (or 200 – 6200 kg/h)

- Refrigerating power 20 – 650 kW

- Ready to plug or for local refrigeration units

- Evaporator for all refrigerants, pump- or dx mode

- Stainless steel completely

- Ideal ice temperature of -0,5°C, not sub cooled

- Chip ice – some cm big

- Dull edges

- Suitable for sensitive products

- Long lasting cooling effect

- No active cooling required at storage

- Steplessly adjustable thickness of ice chips