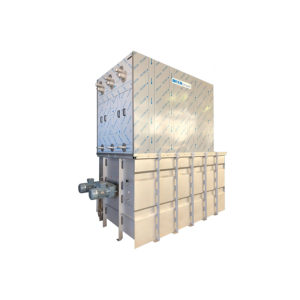

Dimple Plates

The big heat exchange areas ensure a safe process operation with homogeniously guided temperature control. The u-values will only be influenced marginally, when polution or dirt covers the panels. Favourable temperature differences direct at the process media result in a much better efficiency compared to compact external heat exchanges.

At the same time products, especially foods, are treated very gentle. The flexible design of the dimple panels allows tempering of products during other process steps. That secures another separate thermal process step and often increases the product quality.

Fields of Application:

- Industrial chilling of food: fish, meet, poultry, fruit, vegetables, milk, baked godos

- Chilling in the production of chemicals and pharmaceuticals

Benefits:

- Homogenious and conciliatory tempering of products

- Easy access

- Easy cleaning

- Reliability

- Long lifetime due to individually choosen materials

- Any design possible according to application criteria or demand

- Integration into vessels for mechanical and thermal doublefunction

Technical Specifications:

- Sizes from hanky up to 12000 x 2000 mm

- Wall thickness form 0,8/0,8 up to 3/3 mm with double embossed profile

- Up to 12 mm groundplate with single embossed profile

- Rolled plates as well

- Operating pressure up to 20 bar, in special cases up to 50 bar

- Carbon steel or stainless steel as: AISI 304, AISI 316L, AISI 316Ti up to titanium

- Heat exchangers for water, glycol, thermal oil or steam inside the panels

- Evaporators for all refrigerants used as pump system or dry expansion system

- Chanel design according to individual calculation by experienced engineers

- Certification: TÜV, PED, TR CU (GOST)

- Design according to ASME