Vahterus Plate & Shell Heat Exchanger

Vahterus’ unique Plate & Shell Heat Exchanger (PSHE) is at the forefront of heat-exchanger technology. The core is a fully welded plate pack enclosed in a strong shell structure, which eliminates the need for gaskets. Due to its advanced construction, Vahterus PSHE combines the best features of Plate & Frame and Shell & Tube heat exchangers.

PSHE has numerous advantages over traditional heat exchangers. It is compact and low weight, and since it has no gaskets, it can withstand higher pressure and temperatures than Plate & Frame heat exchangers. The structural properties of Vahterus PSHE also make it durable, easy to maintain and energy efficient.

Technical Specifications:

- Process pressure: 16 – 80 bar (other pressure on demand)

- Process temperatures: -80ºC a to 400 ºC (other temperaturas on demand)

- Plate materials: AISI 316L standard (other materials on demand)

- Shell materials: St 35.8/1/P235HG standard

- Refrigerants: Suitable to work with all type of refrigerants and with fluids that are compatible with construction materials used by Vahterus.

Applications:

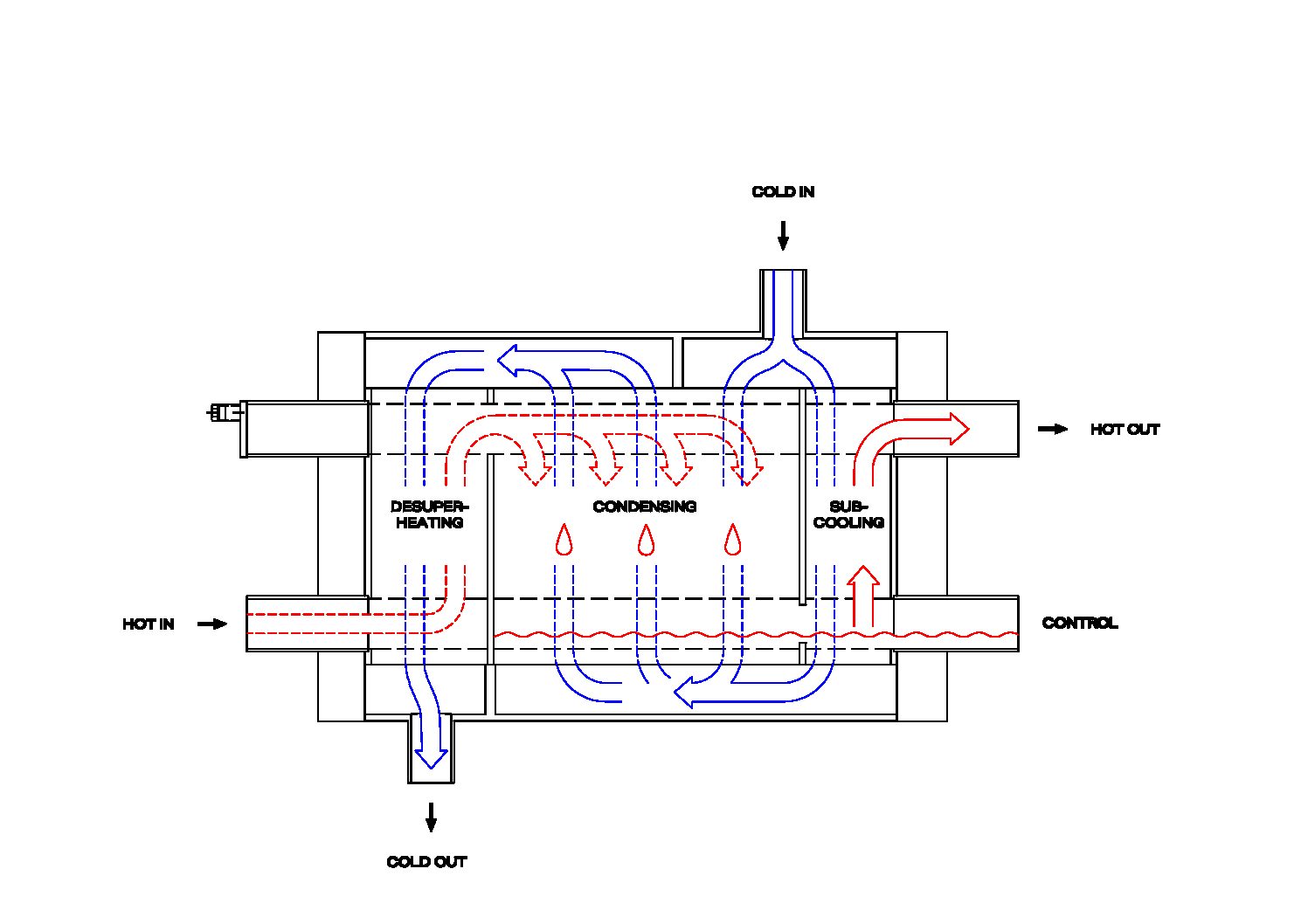

Vahterus’ product range contains nine different plate sizes, which means there’s a suitable plate size for every application. Thanks to advanced manufacturing techniques, Vahterus can provide plates of different thicknesses to meet customer needs. The material of the plate is also chosen individually for every application. After pressing and cutting, the plates are welded together, with the gaps between the plates functioning as channels for hot and cold heat circulation. The plate pack is then installed in a cylindrical shell. Hot and cold circulations run in opposite directions on each side of the plates, and each gap has alternately a ‘plate side’ circulation and a ‘shell side’ circulation. The circulation is directed into the pack of plates and out through combination pipes.

Different applications include:

- Water/glicol coolers with refrigerant (gravity feeded and dry expansion coolers)

- Oil coolers (liquid-liquid – thermosyphon)

- Water cooled or cascade condensers

- Discharge hot gas heat recovery units

- Subcoolers / Economizers

- Other

For more information go to General Plate and Shell Heat Exchangers Catalogue and Private Area (User Manual).

See Catalogue