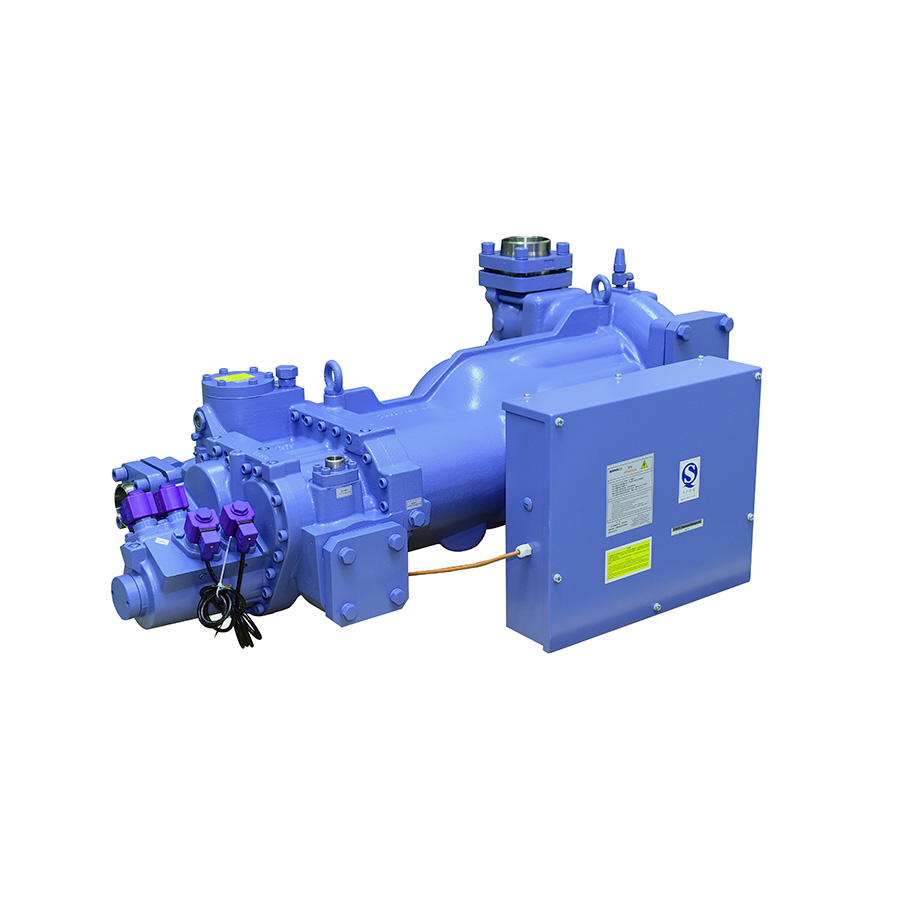

Features of SRM open-type single-stage screw compressor:

- “I”type patented profile, best lobe ratio of 5+7, high efficiency.

- The aluminium windings of the PM motor are compatible with ammonia and need no extra protection which can get damaged or deteriorate over time.

- Rotor is made of high- quality forged steel with micron- machining accuracy, high strength, high wear resistance, and long durability.

- The housing is made of high- strength ductile iron, design pressure: 2.8 Mpa.

- High- precision and wear- resistant roller bearings designed for a life span of 80.000 operating hours.

- The internal compression ratio Vi can be adjusted to the existing operating conditions either manually or automatically for highest efficiency, even under varying conditions.

- Integrated oil channels for secure lubrication of all critical spots within the compressor.

- Suction and discharge ports can be swapped from left to right and turned 360° for easy mounting and connection in multiple compressor systems.

More information:

– See Technical Datasheet:

– Enter the Private Area (Selection program, plans, manuals and instructions).