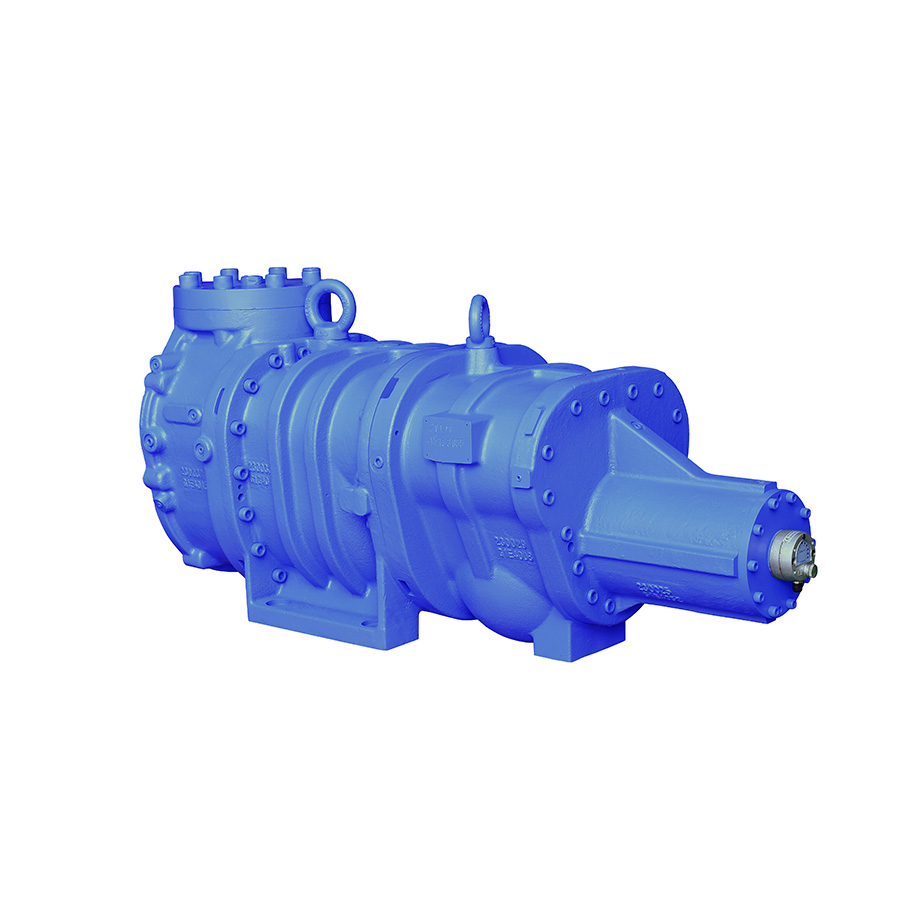

Features of SRM open-type single-stage screw compressor:

- “I”type patented profile, best lobe ratio of 5+7, high efficiency.

- Thanks to the ratio 5-7 the rotor shafts have a larger diameter assuring an increased stiffness.

- Rotor is made of high- quality forged steel with micron- machining accuracy, high strength, high wear resistance, and long durability.

- The housing is made of high- strength ductile iron, design pressure: 2.8 Mpa.

- Innovative shaft seal. The wear- resistant sealing surface is made of silicon carbide for high reliability.

- High- precision and wear- resistant roller bearings designed for a life span of 100.000 operating hours.

- The internal compression ratio Vi can be adjusted to the existing operating conditions either manually or automatically for highest efficiency, even under varying conditions.

- Stepless capacity control (10-100%) by a mechanical slider.

- Integrated oil channels for secure lubrication of all critical spots within the compressor.

- Labyrinth closure between the bearings and screws assuring a clean and refrigerated oil at all the bearings.

- Special internal design that allows a low pressure at all bearings. This assures a sufficient lubrication without the need of an oil pump. The oil pump is only used for a pre lubrication at the start.

More information:

– See Technical Datasheet

– Enter the Private Area (Selection program, plans, manuals and instructions)